This site and its contents are copyright © 2026 Advanced Construction Techniques

Toll Free: 877 373 7248

Toll Free: 877 373 7248

JET GROUTING

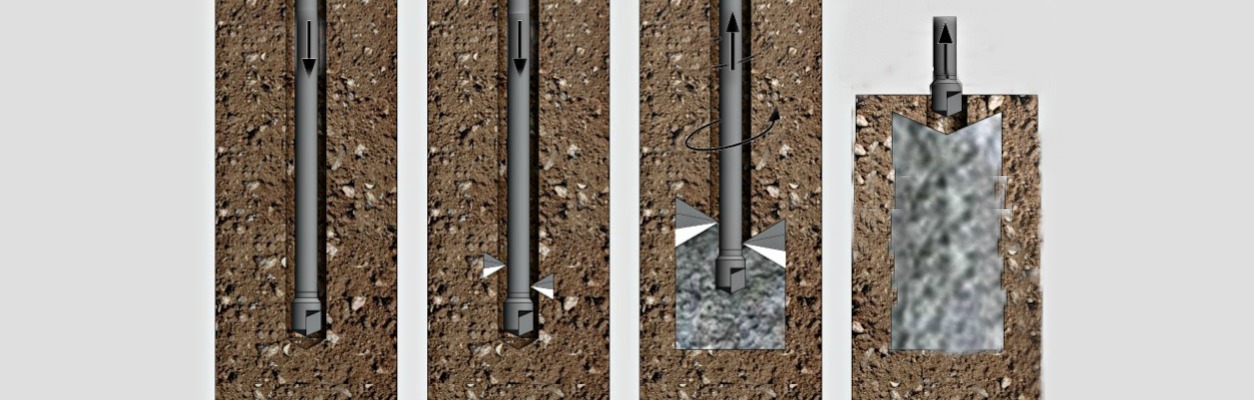

Jet Grouting creates in-situ columns of grouted soil using very high pressure grout injection. Grouting is performed by pumping high velocity jets of grout (or sometimes grout and air or grout, water and air) through the side of a grout monitor, attached at the end of the drill string. The jets erode and mix the soil as the drill string and the monitor are being rotated and withdrawn.

The jet grouting process constructs jet grout panels, full columns or anything in between (partial columns) with designed strength and permeability. Jet Grout column size is dependent on soil type, soil density, injection pressures and flow rates of the various fluids employed, rotation speed, lift rate and type of system used.

It is best practice to perform a pre-construction test program to calibrate, adjust and verify jet grout parameters and the design.

Single fluid jet grouting

The single fluid system is the simplest. This simplicity is due to exclusive reliance on the high velocity of Jetstream to cut, remove and mix the in-situ soil.

Double fluid jet grouting

The double fluid system is the simultaneously injection of high velocity grout stream within a cone of compressed air. The double fluid system is capable of creating a larger column than the single fluid system.

Triple fluid jet grouting

The triple fluid system is the most complicated jet grouting system due to the simultaneous injection of three different fluids, air, water, and grout. The triple fluid system can create the largest diameter of column among the three types.

Always Looking Ahead